Less time to design. Less costs to build. More flexibility.

NAYA Prefabs

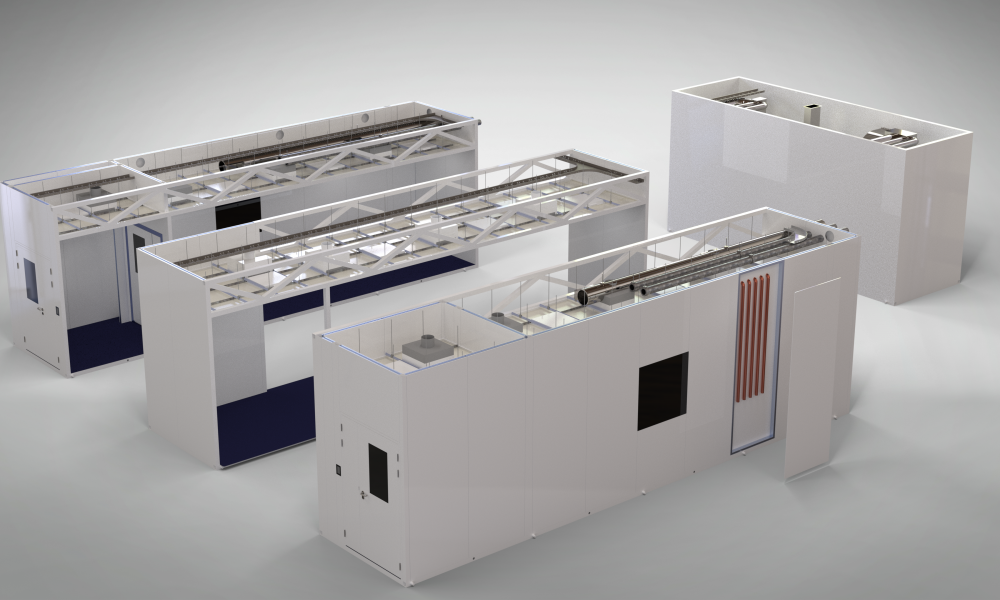

Our prefabricated modular cleanroom solutions, or NAYA Prefabs, are engineered off-site, ensuring rapid deployment, flexible configurations, and adherence to the highest quality and regulatory standards. This approach not only minimizes disruption on-site but also offers unmatched efficiency, making us a trusted partner for industries requiring precision, cleanliness, and speed in production.

Applications

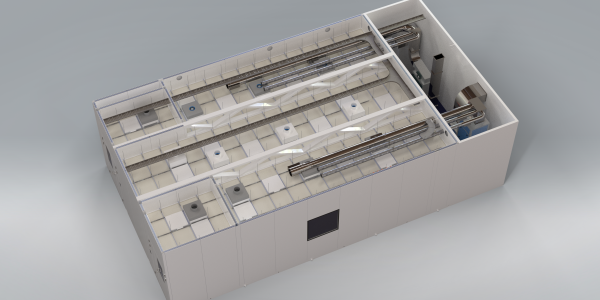

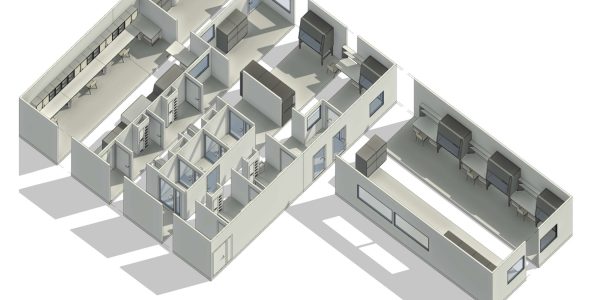

NAYA Prefabs are designed for a wide range of applications, including life sciences facilities for vaccines, mRNA production, cell and gene therapy, tissue engineering, aseptic filling, quality control labs, and more. They are also ideal for semiconductor facilities and operating theaters, providing tailored solutions to meet industry-specific needs.

In-house Manufacturing

Our state-of-the-art 35,000 m2 facility is where the journey of NAYA Prefabs begins. Equipped with the latest automated equipment and technology, this is where all components of our Prefabs are meticulously crafted. After manufacturing, we carefully package and deliver each component to your site, where we handle the installation and ensure a smooth setup.

Customer Care

We ensure your cleanrooms continue to function as intended, even after project close-out. Our post-installation services include maintenance, calibration, and validation to keep your cleanroom operations smooth and compliant. We offer remote monitoring, troubleshooting, on-site support, and staff training to maintain best practices and optimize performance.

Advantages

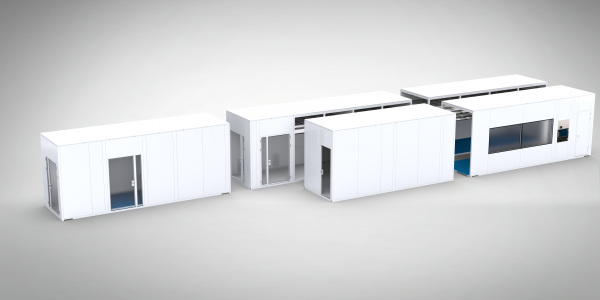

On-site assembly

On-budget & On-time

Scalable

Flexible re-usage of space

Rapid manufacturing & installation

Global shipment options

A pre-engineered, prefabricated solution designed for maximum efficiency, flexibility, and compliance. Built off-site and delivered ready for rapid installation, it meets the highest industry standards, making it ideal for bio-pharmaceutical production and other critical environments requiring strict contamination control.

Fully customizable, scalable approach to creating controlled environments. Built with interchangeable, pre-engineered modules, this flexible solution adapts to your specific needs and can be expanded or reconfigured as your operations grow, ensuring optimal performance, compliance, and cost-efficiency.

A versatile and efficient solution for integrating clean environments into existing facilities. Designed without a built-in floor, they can be seamlessly installed over existing surfaces, reducing installation time and costs while maintaining strict cleanliness and compliance standards. Ideal for applications where flexibility, rapid deployment, and minimal disruption are essential.