We are thrilled to announce that NAYA Life Sciences will be exhibiting at CPHI Milan from October 8-10! As a leader in prefabricated cleanroom solutions, we are excited to connect with industry professionals, innovators, and partners at one of the world’s most important pharmaceutical events.

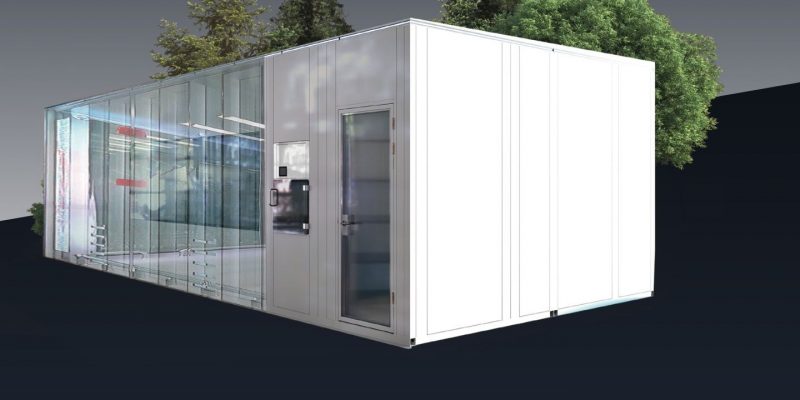

At CPHI Milan, we will showcase our state-of-the-art prefabricated cleanroom solutions specifically designed to meet the needs of the most demanding process technologies. NAYA Prefabs offer unmatched flexibility, rapid deployment, and adherence to the strictest regulatory standards, providing a transformative approach for companies looking to enhance their production capabilities.

Event Details:

- Dates: October 8-10, 2024

- Location: Fiera Milano, Italy

- Stand: 18A67, Zone Pharma Machinery and Equipment

Why Visit Us?

Visiting our stand at CPHI Milan will give you the chance to explore firsthand how our innovative cleanroom solutions can accelerate your production timelines and optimize operational efficiency. Our team will be available to discuss tailored solutions that align with your specific needs, ensuring you stay ahead in a competitive market.

Book a Meeting:

Want to dive deeper into how our solutions can benefit your operations? We invite you to book a meeting with our experts in advance to discuss your requirements and explore our offerings in detail. Secure your spot here.

Don’t Miss Out!

Join us at CPHI Milan and discover the future of cleanroom solutions with NAYA Life Sciences. We look forward to seeing you there and exploring new opportunities for collaboration!