In today’s fast-paced business environment, adaptability and efficiency are crucial. As industries change and evolve, so do their needs for controlled environments. Modular, prefabricated cleanrooms offer a flexible solution that enables businesses to expand and optimize their facilities quickly and with minimal disruption. Here, we will explore the flexibility factor in modular cleanrooms and how they can help you transform your facility quickly and efficiently.

Understanding Modular Cleanrooms

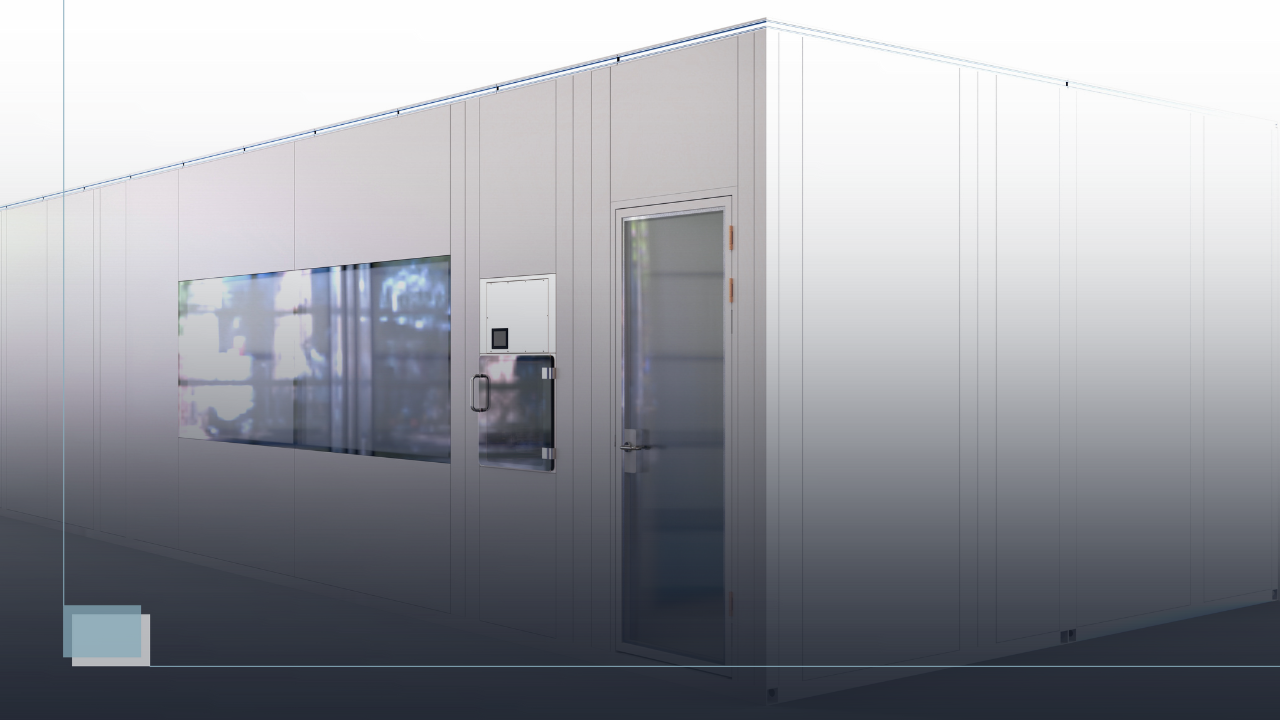

Modular cleanrooms are prefabricated structures designed to meet specific cleanliness standards based on the needs of various industries, such as pharmaceuticals, biotechnology, and electronics. Unlike traditional cleanrooms— which require extensive construction, longer build timelines, and can be costly— modular cleanrooms offer a more versatile and scalable option.

Benefits of Flexibility in Modular Cleanrooms

- Customizable Designs

One of the most significant advantages of modular cleanrooms is their customizable design. This means that the cleanroom provider can tailor the cleanroom layout, size, and features to meet the client’s unique operational requirements. Such customization also allows for the efficient integration of specialized equipment and workflows, optimizing productivity and efficiency. - Scalable Solutions

As businesses grow, so do their cleanroom demands. Modular cleanrooms can be easily expanded or reconfigured to accommodate changing requirements. Whether there is a need to add more space for new equipment or to adjust the layout for increased efficiency, modular systems can adapt quickly to new demands, all while reducing downtime and avoiding costly renovations. - Quick Installation and Relocation

Time is often of the essence in industrial operations. Modular cleanrooms can be designed and constructed in a fraction of the time it takes for traditional cleanroom facilities. Additionally, if operational needs change, modular cleanrooms can be disassembled and relocated to a different area within a given facility or even to a new site altogether. - Cost-Effective

The ability to expand or modify a modular cleanroom without extensive renovation costs makes it a financially sound investment. Traditional cleanroom setups require substantial capital expenditures and long-term commitments, while modular cleanrooms provide a flexible alternative that can align more closely with a given budget. - Regulatory Compliance

Modular cleanroom providers are familiar with the regulations and standards that govern cleanroom environments. By partnering with a reputable provider, you can ensure that your modular cleanroom is designed to comply with industry-specific regulations, whether you’re following FDA guidelines for pharmaceuticals or ISO standards for manufacturing.

Implementing a Modular Cleanroom in Your Facility

When implementing a modular cleanroom, consider the following steps:

- Assess Your Needs: Determine your current and future cleanroom requirements, including the necessary classification, workflow, and equipment integration.

- Choose a Reliable Provider: Select a modular cleanroom provider with a proven track record in your industry. Look for references to ensure you are making an informed choice.

- Plan for Installation: Work closely with your provider to establish an efficient installation timeline, minimizing disruptions to your existing operations.

- Prepare for Maintenance: Discuss ongoing maintenance and support from your provider. Regular maintenance is crucial for ensuring the performance and compliance of your cleanroom.

Conclusion

The flexibility factor in modular cleanrooms presents a transformative opportunity for businesses looking to expand their facilities without the constraints of traditional construction. By offering customizable, scalable, and cost-effective solutions, modular cleanrooms can evolve alongside your operational needs. Investing in a modular cleanroom can enhance productivity, ensure compliance, and ultimately provide a competitive edge in an ever-changing market. Embrace the adaptability of modular cleanrooms, and take your facility to new heights.